Categories

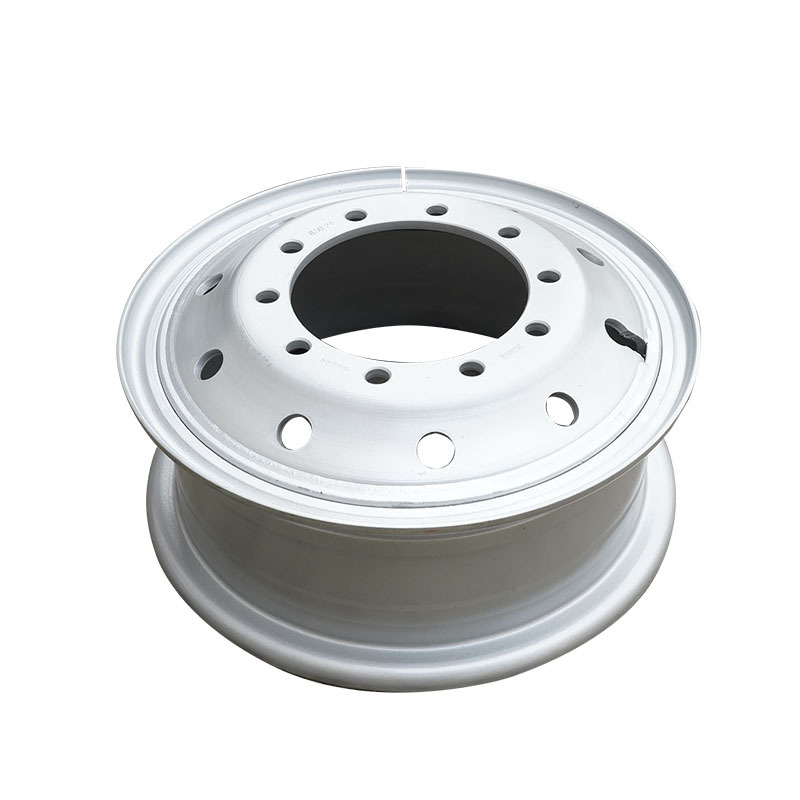

16 inch spoke mining car steel rim top

Key words:

Classification:

- Product Description

-

Product parameters

Material: Aluminum alloy

Specification: 16 inches

Scope of application: Various types of vehicles

Detail features

Strict material selection: High strength aluminum alloy is used as the raw material, which is resistant to impact, not easy to break, and not easy to deform.

Light and agile operation: Lightweight design improves handling performance, good roundness, and allows for easy control of the steering wheel.

Bottom widening: The bottom of the wheel spokes is widened to enhance support strength and match more stable handling.

Strong and High Resilience: Reinforced rib design enhances the sporty feel of the vehicle, with high manufacturing precision and low inertial resistance.

High glossiness: The surface smoothness is high, enhancing visual impact, adding dynamism, and instantly elevating the grade.

16 inch spoke mining car steel rim top is a key component designed for mining cars.

In terms of size, the 16-inch size is suitable for the assembly requirements of many types of mining cars. Its spoke design structure has unique advantages. Spokes can effectively disperse pressure. When the mining car carries heavy objects and travels on complex mining roads, this structure can evenly distribute the pressure from the body and cargo to various parts of the rim, thereby improving the bearing capacity of the rim.

As the top of the steel rim, the selection of steel ensures the high strength and durability of the product. In the harsh working environment of the mining area, frequent ore transportation, bumpy roads and possible collisions require the rim to have strong resistance to deformation and damage. Steel materials just meet this requirement, can work stably for a long time, reduce the frequency of rim replacement, and reduce maintenance costs.

In terms of safety, the design of the rim top meets strict industrial standards. It works closely with components such as tires to ensure the stability of the mining car during driving, avoid safety accidents caused by rim failures, and provide reliable protection for mining operations.

In addition, in terms of production technology, after fine processing and quality inspection processes, each 16-inch spoke mining car steel rim top must undergo strict dimensional accuracy testing, strength testing and other processes to ensure the consistency and reliability of product quality, thereby meeting the high-intensity and long-term operation requirements of the mining area.

相关产品

The same series of products

Steel wheel hub

-

(测试可删)Steel wheel hub

Strictly select materialsAluminum alloy material reduces engine load and increases usage time.

-

Steel wheel hub

Strictly select materialsAluminum alloy material reduces engine load and increases usage time.

-

Steel wheel hub

Casting paint:The product adopts casting technology, and the surface paint process is atmospheric and beautiful.

-

Steel wheel hub

Bold bearings:The aluminum alloy wheel axle is thickened, with strong load-bearing capacity and stable performance.

-

Steel wheel hub

Bottom thickening:The bottom of the wheel mesh is thickened to increase support, which will reinforce and stabilize it during use.

-

Steel wheel hub

A manufacturer that specializes in the research and development, manufacturing, and sales of automotive steel rims, with a complete and scientific quality management system.

-

Steel wheel hub

Strictly select materialsAluminum alloy material reduces engine load and increases usage time.

-

Steel wheel hub

Casting paint:The product adopts casting technology, and the surface paint process is atmospheric and beautiful.

-

Steel wheel hub

Bold bearings:The aluminum alloy wheel axle is thickened, with strong load-bearing capacity and stable performance.

-

OEM matching 8.5-20 rims truck and lorry wheels car tyre rims

Bottom thickening:The bottom of the wheel mesh is thickened to increase support, which will reinforce and stabilize it during use.

-

6.5-16 series steel rims and aluminum alloy wheels exclusively for the market

A manufacturer that specializes in the research and development, manufacturing, and sales of automotive steel rims, with a complete and scientific quality management system.

-

9.0-20 thick steel rims for agricultural machinery, steel rims for automobiles, and wheel hubs

Thickened aluminum material: With sufficient materials and constant temperature production, the wheel density is improved.

-

20 inch forklift wheel hub, steel wheel hub, wheel hub

Good heat dissipation: making the brake drum and tires less prone to aging.

-

forged aluminum alloy wheels

Casting paint:The product adopts casting technology, and the surface paint process is atmospheric and beautiful.

-

heavy-duty aluminum alloy rims

Strictly select materialsAluminum alloy material reduces engine load and increases usage time.

-

20-inch replacement wheel hub

Strictly select materialsAluminum alloy material reduces engine load and increases usage time.

Vacuum wheel hub

-

8.25×22.5 series truck car vacuum steel ring

Electrophoretic coating: safe and environmentally friendly, precision coating, anti-corrosion protection, and extended service life.

-

9.0×22.5 truck vacuum steel ring

More fuel-efficient: lighter in weight and lower in friction compared to steel rims of the same size, saving fuel consumption.

-

Vacuum 22.5 inch wheel rims with twin tires and steel rims

Good rigidity: Good roundness retention, will not deform for a long time.

Wheel rim spokes

-

20 inch spoke steel rim top

High glossiness: The surface smoothness is high, enhancing visual impact, adding dynamism, and instantly elevating the grade.

-

16 inch spoke mining car steel rim top

Strong and High Resilience: Reinforced rib design enhances the sporty feel of the vehicle, with high manufacturing precision and low inertial resistance.

-

9.0x22.5 Finished wheel rims for car making, steel, hard spokes

Casting baking paint: The product adopts casting technology, and the surface baking paint technology is atmospheric and beautiful.

Product inquiry